Aluminum cables or copper cables?

Aluminum cables or copper cables?

With the impact of developing technology, investors are looking for different products that are equivalent to existing products in order to reduce their costs. This search for the cable sector is particularly prominent in the comparison of aluminum and copper used as a raw material in cable production.

Aluminum(Al) and Copper (Cu)

Aluminum is a soft and light metal with a silvery color. It is estimated that the earth is made up of about 8% aluminum. It is very rare in nature. The manufacturing process is very complex and requires a high amount of energy. As a result of electrolysis, aluminum is obtained with a purity of 99.5%. As the foreign substances in the aluminum will reduce the durability of the metal, electrolytic purification method is applied to prevent this and to achieve 99.9% pure aluminum.

Copper is a metal that has a reddish brown color and is found in nature as free or compound. It is one of the most used metals in the world since ancient times because of its soft structure and easy processing. Although it is 0.01% in the earth, it is preferred by mining companies primarily.

Technical evaluation

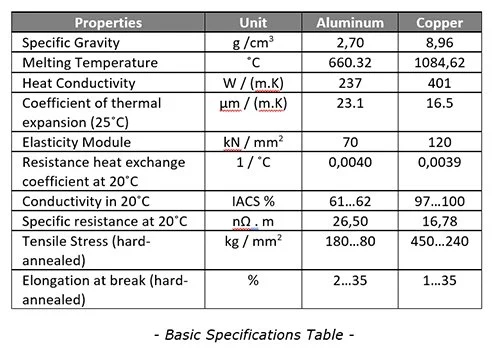

The technical features of aluminum and copper can be summarized under two main headings.

- Physical properties

- Electrical performance

The most important point to consider when considering these two main points is that these features interact with each other. When we physically compare both metals, the most prominent point is their weight. Because the specific gravity of aluminum is lower than the specific gravity of copper. Therefore, the physical properties of the conductors planned to be used gain importance in weight and dimension.

Aluminum, with it’s low specific gravity, is approximately half as lighter than copper. However, when the conductivity properties are considered, the fact that the conductivity of copper is much better than aluminum or the resistance of aluminum is higher than that of copper, means that the physical structure of the aluminum conductor required for the same system is 15-25% higher.

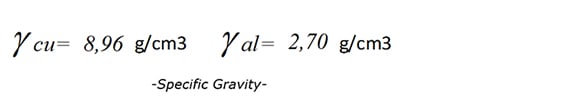

When the conductivity characteristics of these two metals are compared by using the voltage drop formula used in the cable cross-section calculation;

The aluminum conductor cable cross-section that can be used in the same system must be approximately 1.6 times the cross section of the copper conductor. On the other hand, as for electrical performance, (along considering the resistance structure) topics like dielectric properties, impedance characteristics, short circuit resistance, and as for physical performance, the response to temperature increase, fire resistance and mechanical strength should be considered.

When a short circuit occurs, copper conductors protect their mechanical strength better than aluminum conductors. The use of aluminum may cause pulling and twisting of the rigid conductors, while it may cause bending, loosening or compressing of the flexible conductors.

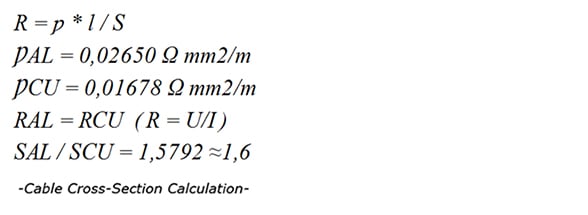

Aluminum conductors are not as durable as copper conductors to vibration, cracking and breakages. Mechanical fatigue occurs when exposed to repeated loading and unloading stresses and may cause microscopic cracks. These cracks can reach critical extents over time and can lead to large breaks.

When we examine the thermal conductivity, the heat formed under the current is distributed much faster by the copper conductor. This is an important feature in the transfer of heat, for example, during the overcurrent draw of any motor. Preferring a smaller diameter for the conductor allows the heat to be transferred quickly to the surface in a shorter way.

Thanks to its high melting temperature, the copper element can withstand the mechanical forces that occur in thermo-active processes (expansion, contraction, etc.) without losing its mechanical properties.

One other important factor in the selection of conductive materials is the connections and joints. There are four main mechanisms affecting electrical connections. These are:

- Oxidation

- Galvanic effect

- Cold flow / Creep

- Thermal expansion

Oxidation: Oxide, which causes reduction in the metal-to-metal contact or increased contact resistance at the connection point, consists of sulfide or inorganic films. This effect may cause the contact surface to warm up and increase the temperature at the connection point, resulting in malfunction. In contrast to aluminum, copper joints rarely overheat and do not require any surface preparation or usage of antioxidant compounds.

Galvanic effect: When aluminum and copper come into contact with each other, aluminum can physically lose its structural property by electrolytic effect. The connection point is both mechanically and electrically deteriorated due to a reduction of the contact surface or corrosion. For this reason, an aluminum conductor used in conjunction with equipment and accessories such as contact seals, bimetallic termination or use of special equipment needs implementation of a series of insertion techniques.

Cold flow / Creep: Pressure is applied to create a good connection structure and to ensure high contact of the conductors. This operation may cause the metal to “flow”, therefore to deform. While this effect is mostly seen in aluminum conductors, the effect for a copper conductor, which is more rigid, is so less that it is not significant. When the conductor is under stress, the deformation of metal depending on the level, duration and temperature of the stress, is called “creep”. Both cold flow and creep lead to decreased contact pressure, increased joint resistance, and thus, overheating. Aluminum creeps more than copper, faster and at lower temperatures.

Thermal expansion: While no relaxation is observed at the connection points made with copper-copper, brass-copper or cable lugs which thermal expansion of aluminum conductors can cause loosening over time. Increased contact resistance increases the overheating and arc potential, thus increasing the risk of fire. Joint connections with copper are stronger, more resistant to corrosion, more reliable and durable (because they are less sensitive to cold flow and thermal effects) than aluminum joint connections.

Installation Structure and Cost

Whether the cables are aluminum or copper, they are subjected to successive bending or pulling forces at turning points during installation. These bends cause the conductor to be physically forced/strained. To cope with this, the conductor must have a flexible structure. The cables which are prepared according to the international TS EN 60228 production standard are divided into four classes.

- Class 1: Solid conductors

- Class 2: Stranded conductors

- Class 5: Flexible conductors

- Class 6: Conductors with flexibility more than Class 5.

While the use of both aluminum and copper materials is permitted for the production of Class 1 and Class 2 conductors, for the production of conductors of class 5 and 6, only the usage of copper is allowed. The reason for this is that the copper is flexible. The same standard allows production only in sections of 10 mm² and above as minimum dimension in order to provide sufficient strength in aluminum conductors.

The permitted bending radius in the TS EN 60228 and TS EN 50565-1 standards may vary from 2 times to 15 times the cable diameter. However, for cables with the same current carrying capacity, it would be inevitable to install it with a larger bending angle as the aluminum cable would have a larger cross section.

When we look at energy savings and CO2 emissions, among the metals that transmit the electricity and heat best, copper stands out. The low resistance of copper plays a significant role in improving the energy performance of the devices and units in which it is used, and contributes to the reduction of CO2 gas emissions produced by saving energy.

Considering the cost of installation, operation and maintenance, the investment cost of aluminum is more favorable than copper, but when the cost of maintenance of these metals, installation equipment, manufacturing costs and installation labor are included in the total cost, the cost advantage of aluminum is almost eliminated.

Aluminum and Copper cables comparison sample

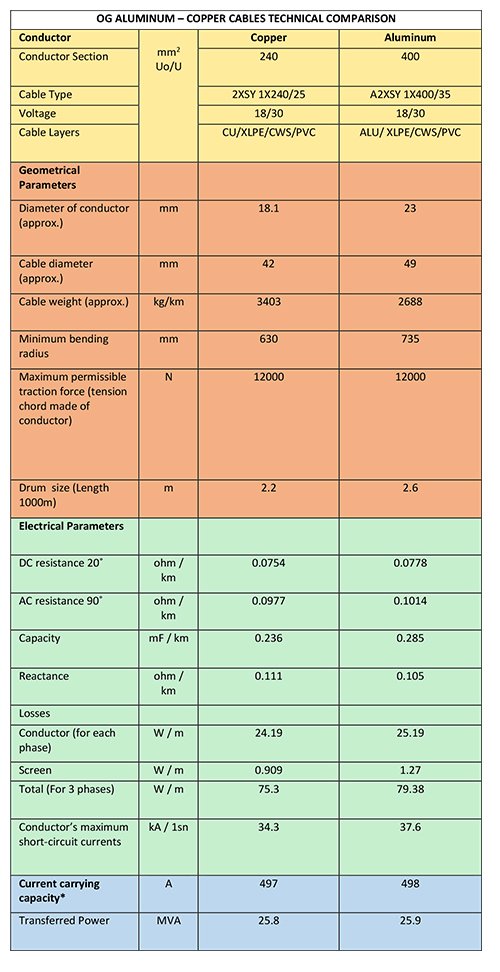

In the comparison table example, comparison of the technical values (which we mentioned in our article) of aluminum and copper cables, which have the same current carrying capacity, can be seen. If aluminum conductor is used according to this table;

Cable total diameter increases by 17%,

Conductor diameter increases by 27%,

Bending radius increases by 17%,

Drum size increases by 18%,

Conductivity resistance increases by 3.8%,

Conductor losses increase by 4.1%,

Display losses increase by 40%.

For this reason, when comparing the aluminum cable with the copper cable, not only the cost of purchasing should be taken into consideration, but also the suitability of the technical conditions to the structure of the enterprise and the effect it has or might have on the operating costs.

Türk Prysmian Kablo ve Sistemleri A.Ş.

e-posta: [email protected]