Chemical Resistance Solutions

Prysmian continues the development of product ranges to help customers in applications where cables need to operate in areas where they may be vunerable to attack by oil, water or chemicals.

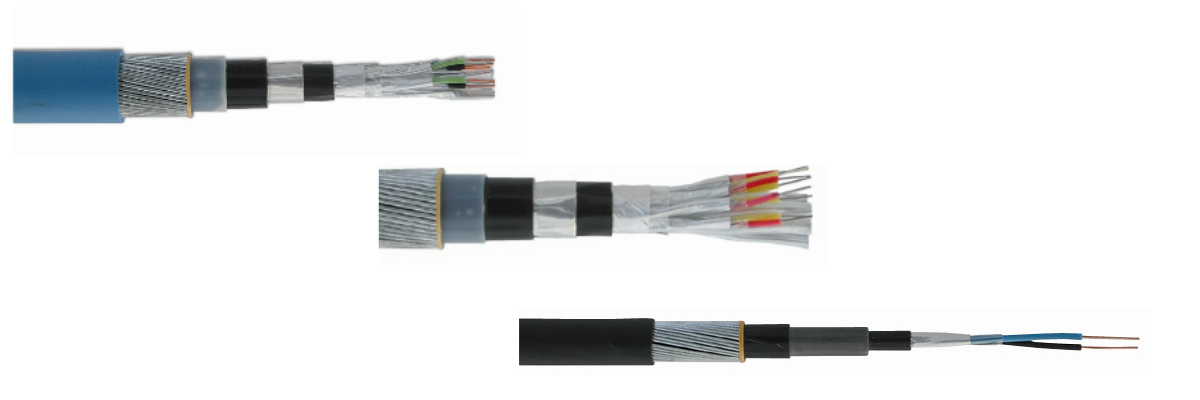

The DRYLAMTM Hydrocarbon Barrier Sheathing System is an example of this innovation pipeline.

The DRYLAMTM system enhances a cable's resistance to penetration by humidity or aggessive chemicals.

The system has a modular design based on a co-polymer coated aluminum tape and a polyamide extruded sheath that resists corrosion, gives enhanced mechanical properties and an electrical screening equivalent to a 2 mm lead sheath.

DRYLAMTM can be applied to all Prysmian cables including medium and low voltage power cables, control and instrumentation, fibre optic and thermocouple extensions and copper data, coaxial and signalling cables.

DRYLAMTM removes the need to use a lead sheath so, in addition to excellent performance, it will not suffer from cracking and is a more environmentally sustainable solution.

The first DRYLAMTM product was supplied in the early 1990s and, in addition to decades of outstanding performance in customer installations, it has been extensively tested by reputable third party laboratories who have conducted aging tests and confirmed its resistance to a wide range of aggressive fluids encountered in the Oil & Gas industry.

The cable protected with the DRYLAMTM system is smaller, more flexible and lighter then a traditional lead sheathed cable, so has lower installation & logistics costs for new installations and can use existing cable trays when applied during an upgrade.