Kablolardaki İletken Tipleri

Kablolardaki İletken Tipleri

1. What is the CONDUCTOR?

It is an insulated or uninsulated wire or bundle of wires and consisting of one or more wires, used to transmit electrical energy.

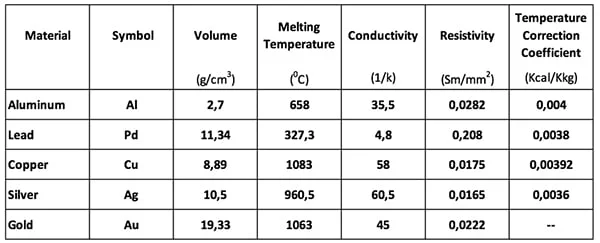

2. What are the materials used in CONDUCTOR?

The material should be selected according to the usage and purpose of the cable.

Generally;

Low voltage indoor installation cables: Copper,

Low voltage and medium voltage energy cables: Copper or aluminum,

High voltage underground and submarine cables: Copper or aluminum,

High voltage overhead line cables: Steel-core aluminum conductors are used.

HISTORY OF COPPER WIRE STANDARDS IN THE WORLD

Electrical properties of copper wires, the values obtained as result of the studies carried out by the establishment of the IASC in 1913 which accepted as standard by IEC in 1925 and was first published in the IEC 28 standard.

DEVELOPMENT AND HISTORY OF CONDUCTOR AND CABLE STANDARDS IN TURKEY

With the establishment of TSE at the end of 1960, the IEC 28 standard was translated into Turkish and published with the number TS 288 in 1965.

As a result of the studies carried out within the scope of the development of the sector and the dissemination of standards, TS 1 "Copper Wires Used in Electricity" was accepted as a standard and published in 1973.

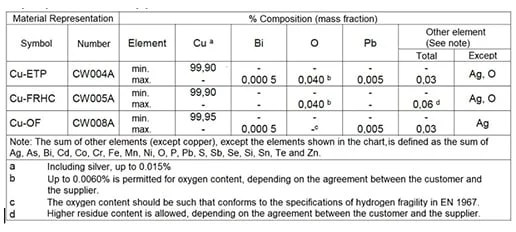

National standards were canceled and EN standards were published instead.

Within this scope, national standards of TS 2, TS 16, TS 17 and TS 18 were canceled in Turkey and TS EN 13602 standard has been published instead.

Generally, it is recommended to use Cu-ETP type copper in energy cables and Cu-OF type copper in signal and communication cables.

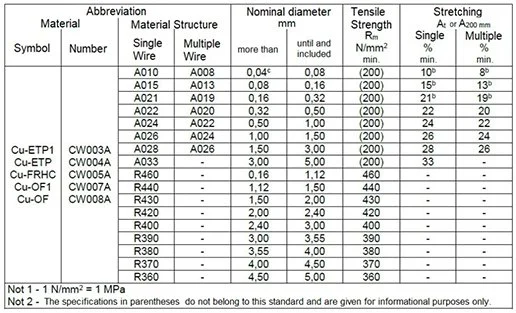

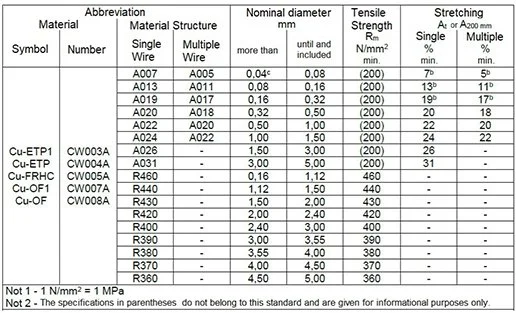

The physical properties of copper wires are defined in Table 2 of EN 13602.

The mechanical properties of copper wires are defined in Table 3 of EN 13602.

The electrical properties of copper wires are defined in Table 4 of EN 13602.

3. What are the types of CONDUCTOR?

Copper conductors used in energy cables are generally manufactured according to IEC 60228 standard or they are manufactured according to national standards prepared by reference to this standard.

TSE translated this standard into Turkish and publishedwith the number of TS EN 60228 in 2005.

Conductors are divided into 4 categories for the purpose of use;

- Class 1: Solid conductors,

- Class 2: Stranded conductors,

- Class 5: Flexible conductors,

- Class 6: Conductors with flexibility more than Class 5

Class 1 (Solid conductors):

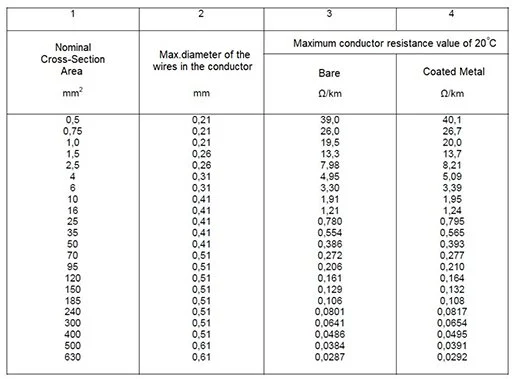

They are manufactured as bare or metal coated, from round single wire and generally in the range of 0.5-16 mm² for the intended use.

- Which cable types have Class 1 conductors?

H05V-U, H07V-U, H05Z1-U, H07Z1-U and conductor cross section ≤16mm2 of NVV, YVV, YVCV, YVZ2V, NHXMH, N2XH, N2XCH, N2XRH, YXV, YXCV, YXZ2V type cables are manufactured with Class 1 conductors, unless if there isn't any different demand.

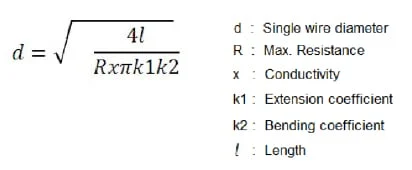

Single wire diameter can be calculated with the formula below.

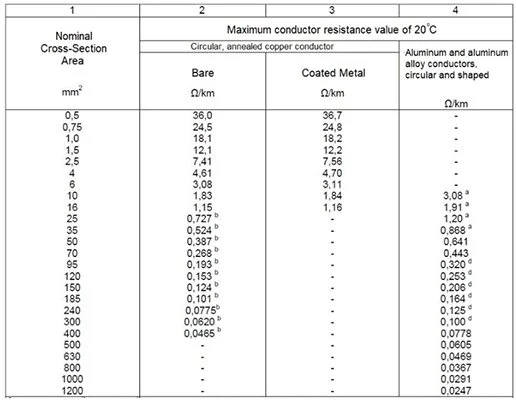

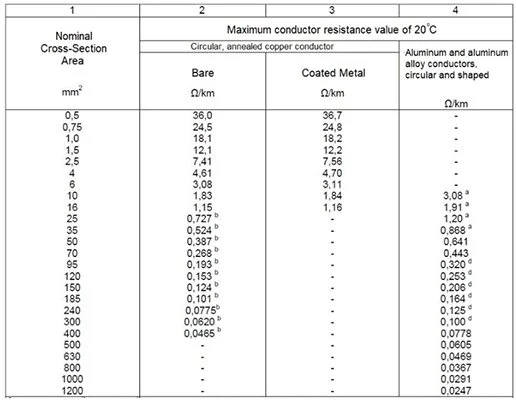

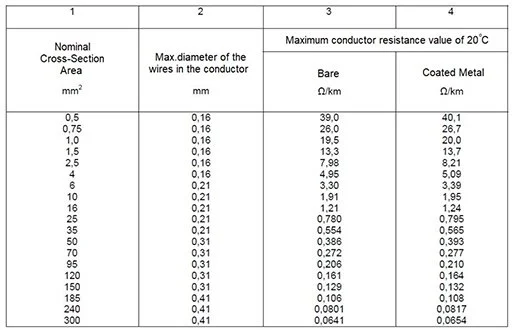

The values of maximum DC resistance and maximum conductor diameter are specified in Table.1 and Table C.1. in TS EN 60228.

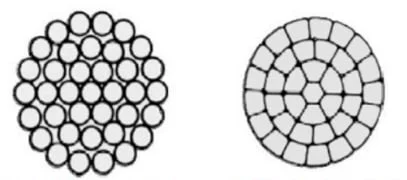

Class 2 (Stranded conductors):

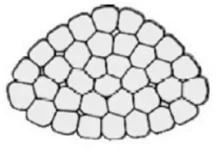

They are manufactured as bare or metal coated circular, compacted circular or sectoral form for the intended use;

For Circular; range of cross section between 0.5 - 1200 mm²

For Compacted Circular; range of cross section between 16 - 1200 mm²

For Sectoral Form; range of cross section between 35 - 400 mm²

Although the use of cable conductors of sector form isn't common in Turkey, they are widely used in Central and Northern European countries.

- Which cable types have Class 2 conductors?

LV building and control panel cables,

H05V-R, H07V-R, H05Z1-R, H07Z1-R ve AG bina içi ve dışında kullanılan güç ve kumanda kabloları, iletken kesiti > 16 mm² olan, NVV, YVV, YVCV, YVZ3V, N2XH, N2XCH, N2XRH, YXV, YXCV, YXZ2V.

Shipboard cables with screen and without screen, 1XZ1-R, 1XC4Z1-R, 1XC7Z1-R, 1J2XC4Z1-R, 03XPC4Z1-R, 03J2XPC4Z1-R,

M.V and H.V cables, YXC7V-R, YXC8VZ3V-R, YXC7Z1-R, YXC8Z1Z3Z1-R, YE3S(AL)E

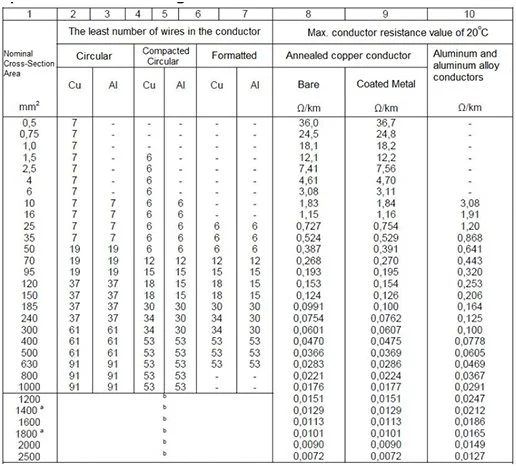

- What are the main properties of Class 2 conductors?

- Compliance with the largest DC resistance as defined in Table 2,

- Compliance with the minimum number of wires as defined in Table 2,

- Compliance with the largest conductor diameter wires as defined in Table C.1.

Class 5 and Class 6 (Flexible conductors)

They are manufactured as bare or metal coated as circular, for the intended use. They are usually used in low bending radius or moving facilities.

- Which cable types have Class 2 conductors?

H05V-K, H07V-K, H05Z1-K, H07Z1-K, H03VV-F, H05VV-F, H05VV5-F, H05VVC4V5-K, H05VVH6-F, H05RR-F, H07RN-F, 052XZ1-F

- Which cable types have Class 6 conductors?

H01N2-D, H01N2-E

- Why are Class 5 conductors called F or K?

F - Cables that are allowed for moving use,

K - Cables that are not allowed for moving use.

- What are the main properties ofClass 5 and Class 6 conductors?

- Compliance with the largest DC resistance as defined in Table 3 & 4,

- Compliance with the minimum number of wires as defined in Table 3 & 4,

Compliance with the largest conductor diameter wires as defined in Table C.1.

Türk Prysmian Kablo ve Sistemleri A.Ş.e-posta: [email protected]