Improved Fire Alarm Cable with Impact and Water Resistance

Abstract

Nowadays, cables that continue to function in fire environments, prevent the spread of flames, do not emit toxic gases, have low smoke density, do not create corrosive environments, and are halogen-free are widely used in residences, workplaces, infrastructure, and industry. Thanks to these fire-resistant cables, which are increasingly used, safer and healthier living spaces are being created. The use of these cables is of great importance to prevent loss of life and property in the event of a fire. The increase in the use of fire-resistant cables has led cable manufacturers to work on making the cables even safer. Considering fire conditions, the resistance of fire alarm cables to water and impact, in addition to flames, is undoubtedly of great importance. This study describes the structure of the developed fire alarm cable and the tests applied. The developed cable is suitable for use in areas where high levels of fire resistance are required and provides successful results against the most challenging fire test standards in the industry.

1. Introduction

Fires that occur for various reasons cause both loss of life and property. Fires often start with a spark and quickly spread. It is also known that the flame-conducting properties of the main materials of many products used in daily life have a facilitating effect on the spread of fire.

Firefighting is carried out in different ways. The detection and notification time of the fire are important parameters for extinguishing the fire. It has been known for a long time that the notification time is critical, and traditional fire alarm buttons and fire extinguishing devices have been considered solutions in crowded places such as schools and hospitals for years. Traditional fire alarm buttons are being replaced by innovative electronic fire alarm systems that act as early warning devices through heat, smoke, and various sensors. The aim is to minimize the notification time with electronic fire alarm systems. It is important that the fire alarm cables used in these systems maintain circuit integrity under fire.

Preventing the spread of fire is as important a parameter as the detection and notification time of the fire. With developing technology, the variety and quantities of cables used inside buildings are increasing. Since cables are thought to mediate the spread of fire, in recent years, it has become a standard for indoor cables to be flame-retardant.

Despite all the precautions taken, it is desired to extinguish the fire quickly in case of a fire. For this purpose, electronically controlled, sensor-equipped fire extinguishing systems have been developed, providing a safe solution independent of human power and without risk. In these systems, many electronic devices are interconnected via cables.

At this point, the quality of the cables used as fire alarm cables is as vital as the installed systems. In addition to fire alarm systems, the widespread use of fire extinguishing systems has created a need for differentiation in the cables used in alarm systems. When the fire environment is simulated, it is known that there are fallen and overturned objects in the environment, as well as water sprayed by fire extinguishing systems, in addition to flames. Under these conditions, the environment cables must transmit signals under flames, even in impact and wet environments. New generation fire alarm cables, referred to as developed fire alarm cables, play an important role in creating safer living spaces.

It has been determined through unfortunate incidents that cables that are not resistant to impact and water cannot provide transmission during fire and fire extinguishing, causing short circuit failures. As seen during a fire, new generation fire extinguishing systems are actively engaged in extinguishing the fire. Other desired features in fire alarm cables are that they do not emit smoke and toxic gases under flames and are halogen-free. It is known that most deaths during a fire are due to suffocation and poisoning. The smoke and flames generated during a fire are shown in Figure 1.

2. Cable Design

Fire alarm cables are used in fire alarm systems. These cables are designed to continue functioning under flames, do not emit smoke, do not contain toxic gases, and are used as indoor signal transmission cables. With the development of advanced fire alarm cables, the aim is to produce safer cables that can operate in more challenging fire environments. In addition to fire alarm cables known by the code JE-H(St)H FE180, the fire resistance performance of cables used as indoor signal and control cables, such as LiHCH FE180 and LiHH FE180, has also gained importance. In the structure of the JE-H(St)H FE180 fire alarm cable, LS0H (Low Smoke Zero Halogen) material, which does not emit smoke and toxic gases, is preferred for insulation and sheath materials suitable for indoor use.

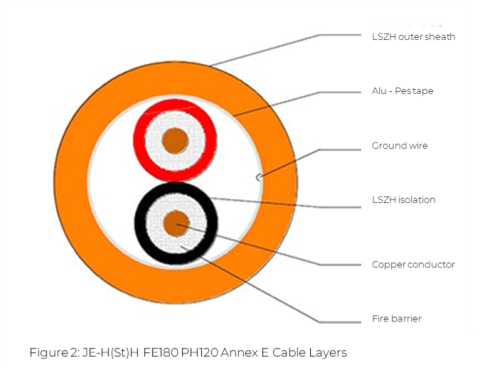

A special tape that acts as a flame barrier is helically wrapped around the conductor made of copper wire. After wrapping foil over the flame barrier, LS0H insulation material of sufficient thickness to meet electrical properties is extruded to form the cores. For 2-pair cables, the cores are twisted together in a star quad configuration, and for cables with 4 pairs or more, units are formed and twisted into bundles to create the cable core. After wrapping a polyester tape (optional) with holding and protective properties around this core, a longitudinally tinned copper ground wire and one layer of aluminum-coated polyester tape screen are wrapped to ensure the continuity of the screen. An orange LS0H sheath is applied over the screen. The cable layers are shown in Figure 2.

The physical appearance of the cable is shown in Figure 3. Here, the conductors, cores, grounding wire, aluminum foil, and sheath layers can be seen in detail.

3. Fire Tests

The following tests are applied to standard fire alarm cables: IEC 60754-1/2 halogen acid gas test, IEC 61034-1/2 low smoke density test, IEC 60332-1-2 flame propagation test, IEC 60331-21 fire resistance test, and EN 50200 impact fire resistance test, along with the additional Annex E of the EN 50200 test standard.

The applied tests are described below:

IEC 60754-1/2: This test measures the corrosiveness, pH, and conductivity values of gases released during combustion. Required values: HCl < 0.5%, pH ≥ 4.3, c ≤ 10μS/mm.

IEC 61034-1/2: The IEC 61034-1/2 test standard involves measuring the light transmittance of smoke released from a 1-meter-long cable burning in a 3x3x3m (27m³) cubic closed test room with a fuel mixture of 90% ethanol, 4% methanol, and 6% water. Light transmittance should be at least 60%.

IEC 60332-1-2: This test simulates flame propagation in a fire environment. For cables with a diameter less than 25 mm, the flame is applied to the cable at a 45-degree angle for 60 seconds. The burning part must maintain a distance of at least 50 mm from the lower part of the upper support point. Similarly, flame spread should not exceed 540 mm.

IEC 60331-21: This is the standard test for circuit integrity under fire conditions. In this test, continuity of transmission is required for 90 minutes in an environment of at least 750°C. This test has been conducted for 180 minutes as per Prysmian standards.

EN 50200: This standard covers the test method for cables designed to be used as emergency circuits for alarm, lighting, and communication purposes and to be fire-resistant. This test method can be applied to cables with metallic conductors up to 2.5 mm², an outer diameter not exceeding 20 mm, and a rated voltage not exceeding 600/1000 V. The ambient temperature during the test should be 25 ± 15°C.

The test setup consists of five main parts:

- A vertical wall made of heat-resistant, non-combustible material attached to steel supports, on which the cable is mounted.

- A transformer that is the source of the current applied to check continuity during the test.

- A horizontally mounted flame source device applied to the sample cable during the test.

- A device that produces sudden impacts.

- A water spray device.

Figure 4 shows the test setup.

The sample to be tested must be at least 1200 mm in length, with approximately 100 mm stripped from each end for electrical connection. The cable, symbolically shaped into a “U,” should have its bending points based on the declared minimum bending radius for the cable.

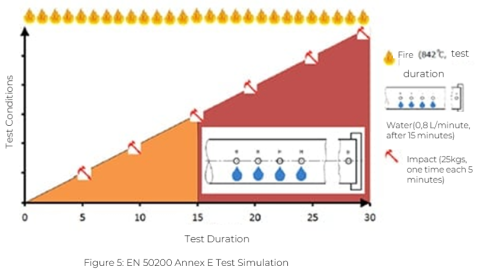

The cable is mounted on the test setup so that the distance between the vertical parts of the cable is approximately 475 mm. After activating the propane flame source device, which provides a constant temperature of 842°C, the electrical power supply should be turned on, the sudden impact device should be operated, and the test duration timer should be started. The sudden impact device, weighing 25 ± 0.2 kg, should strike the test wall 5 minutes ± 10 seconds after activation and then at intervals of 5 minutes ± 10 seconds.

The classification of cables for fire resistance is described in Annex D. The performance criterion is the continuity of power supply or signal. The duration for which the cable maintains its function (e.g., 15, 30, 60, 90, or 120 minutes) determines the cable class. As a result of this test, cables are classified as PH30, PH60, PH90, or PH120.

In addition to the fire test under impact, the water spray test described in Annex E is a test that takes the cable’s robustness and reliability to a higher level. According to the standard, after applying flame and sudden impact for 15 minutes, water spraying should start at a flow rate of 0.8 ± 0.05 l/min. The application of water should continue until the end of the test. If the cable maintains its function for a total of 30 minutes, it means the cable passes the test. The graphical explanation of the test is shown in Figure 5.

4. Conclusion

In order to ensure the safety of life and property, the measures taken against fire have changed dimensions today. Developments in fire alarm and fire extinguishing systems have increased the need for fire-resistant cables. Especially in critical areas such as alarm systems, it is expected that the cables used will work safely in full compliance, considering the effects in a fire environment. Current fire alarm cables maintain circuit integrity for 120 minutes in impact and fire resistance tests conducted in accordance with the EN 50200 standard. The newly developed product provides resistance to the conditions of EN 50200 Annex E, exceeding the combustion performance of standard fire alarm cables.

In addition to the effects of fire and impact, a water effect was applied to the cable during combustion, thus maintaining circuit integrity for a total of 30 minutes—15 minutes under impact and 15 minutes under impact and wet conditions. In a fire environment, water sprayed from firefighter hoses and fire extinguishing systems causes the cable to come into contact with water in addition to flames and impact. This cable, developed as a solution against water effects, offers a safer solution compared to standard fire alarm cables.