Fiber Optic Cables Protected Against Rodents

1. Introduction

The telecommunications sector is undoubtedly one of the most prominent sectors in recent years. The importance of communication has reached an indisputable level and has become an indispensable freedom for people. The role of the cable sector is quite significant in the infrastructure of technology that has entered every aspect of daily life. Communication cables can generally be divided into copper and fiber optic cables.

2. Damage of Rodents to the Cable

Depending on the location and method of installation, cables can be exposed to various hazards and attacks. One of the most significant causes of these hazards or attacks is rodents. Rodents can cause substantial damage to cables by biting or gnawing on the outer sheath.

To protect against such damage from rodents, rodent-resistant cable designs have become increasingly important today.

3. Methods of Protection Against Rodents

Rodent protection methods can be categorized under five main headings:

1. Application of a metallic layer/armor on the cable core or inner sheath.

2. Application of armor made of non-metallic materials such as flat GRP (Glass Reinforced Plastic) or flat FRP (Fiber Reinforced Plastic) on the cable core.

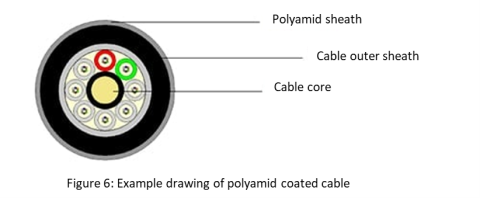

3. Application of a special polyamide sheath on the cable outer sheath.

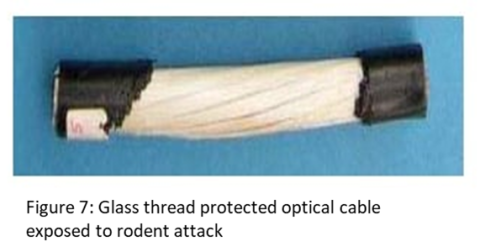

4. Application of glass yarn at a certain density on the cable core or inner sheath.

5. Application of chemical additives to the cable outer sheath.

The protection methods applied may vary depending on the area where the cable is installed or the installation method.

3.1. Application of metallic layer/armor on the cable core or on the inner sheath This method can be applied in three different ways:

3.1.1 Application of longitudinally corrugated steel tape coated with copolymer on the cable core or inner sheath.

3.1.2 Application of helically wound galvanized steel tape or tapes on the cable inner sheath.

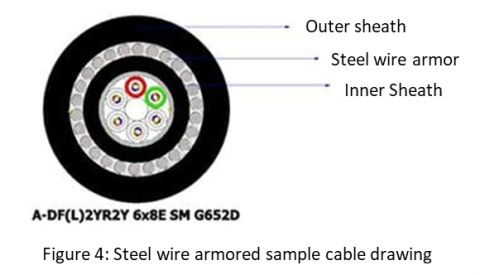

3.1.3 Application of galvanized steel wire on the cable inner sheath.

3.1.1. Copolymer Coated Corrugated Steel Tape Armoring

This is one of the most commonly used methods for protecting fiber optic cables. Today, many telecom operators use copolymer-coated steel tape for rodent protection. With copolymer-coated corrugated steel tape, the cable core is effectively 100% protected from rodent attacks. Corrugated steel tape cables are more flexible compared to galvanized steel tape and galvanized steel wire cables. Additionally, the diameters and weights of these cables are lower than those of galvanized steel tape and steel wire cables, which facilitates easier installation. As seen in Picture 3, even if the outer sheath of the cable is damaged by a rodent, the rodent cannot reach the cable core due to the steel layer, thereby protecting the cable core and fibers from rodent attacks.

3.1.2. and 3.1.3. Galvanized Steel Tape and Galvanized Steel Wire Armoring

In general practice for fiber optic cables, galvanized steel tapes or galvanized steel wires are placed between the inner and outer sheath. In this structure, the cable core is effectively 100% protected from rodent attacks. These types of cables are used in areas with heavy operating conditions, such as high crushing force, high impact resistance, or high tensile strength.

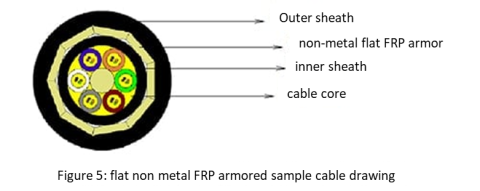

4. Non-Metallic Called Flat GRP or Flat FRP On the Cable Core Application of Armor Made of Material

This method is generally used in fiber optic cables that do not contain metal elements. In this method, a special non-metallic material called flat GRP (Glass Reinforced Plastic) or flat FRP (Fiber Reinforced Plastic) is applied to the cable core or between the inner and outer sheath. Thanks to this non-metallic armor, the cable is protected from rodent effects. Another advantage of these types of cables is that there is no need for grounding since there is no metal layer in the cable.

5. Application of Special Polyamide Sheath on Cable Outer Sheath

It is the application of a thin (0.5 mm-0.8 mm thick) sheath on the outer sheath. The polyamide sheath also provides protection against termites and ease of installation for the cable. Special polyamide is a hard material with a hardness level above 70 shore.

6. Glass Thread of a Certain Density On the Cable Core or On the Inner Sheath

In recent years, a method that has been increasingly applied to protect fiber optic cables against rodents involves the application of glass yarn at a certain density (weight) on the cable core or inner sheath. This effectively protects the cable against small rodents. Even if rodents damage the outer sheath of the cable, they cannot penetrate the glass yarn layer to reach the cable core. One of the main reasons rodents cannot reach the cable core is that the glass yarn breaks and pricks the rodent’s mouth or tongue. As a result, the rodent gives up the desire to bite or chew.

7. Application of Chemical Additives to the Cable Outer Sheath

In this method, special additives that are irritating to rodents are added to the outer sheath of the cable. These additives protect the cable by leaving a bad taste or emitting an unpleasant odor when a rodent approaches or bites the cable.

8. Conclusion

In conclusion, since fiber optic cables can be installed directly in the ground, pipes, or concrete channels, they can be manufactured in various structures. Therefore, different protection methods against rodents can be used. Based on the experiences gained, the most effective protection method is the application of metal layers described in Item 1. However, for non-metallic cables, different protection methods described in Items 2, 3, and 4 are also available.

9. References

(1) B03: Rodent protection (Draka),

07-All- Dielectric-rodent-resistant-tactical-cable (Draka-DCB HDTV09 1010)