Solar Cable System Issues in Applications and Recommended Solutions

1. Introduction

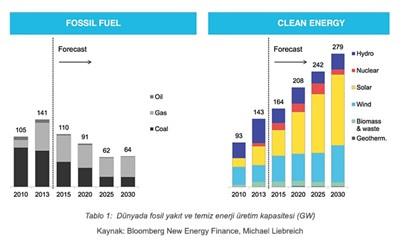

As in the rest of the world, renewable energies are gaining more importance in our country’s energy policy every day. Among these, solar energy has taken a significant position among renewable energy sources with its rising trend in recent years. The solar (PV) cables used in a solar power plant, which are most exposed to external influences, must comply with relevant international standards. The conditions they must meet and the selection criteria for these cables are crucial for the lifespan and efficiency of the plant.

2. What is Renewable Energy?

The technological advancements of the twenty-first century are indeed paving the way for a more comfortable future. The increase in electronic devices in our homes, the use of multiple cars in families, and many other developments highlight this progress. However, this progress also necessitates that we develop effective and lasting solutions to impending threats. One of the most crucial solutions is alternative renewable energy. Renewable energies are practically unlimited sources that meet fuel requirements from nature. While the methods of harnessing nature’s energy vary, it’s essential to remember that the sun is the fundamental source of all energy. Renewable energy technologies are advancing daily, leading to more efficient energy production from these sources.

3. Where is Turkiye in Renewable Energy?

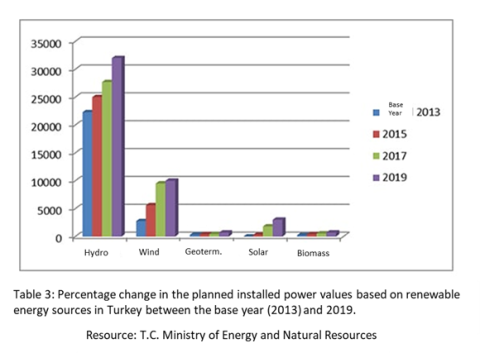

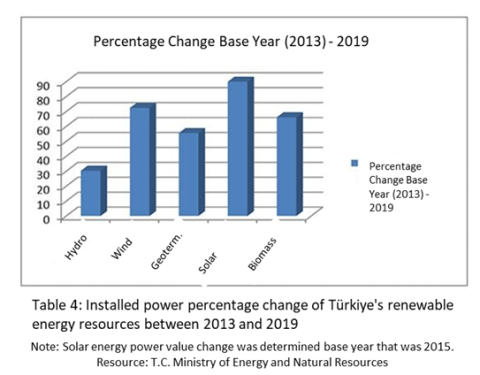

In terms of renewable energy potential, Türkiye is more advantageous compared to fossil resources. The potential for hydraulic, wind, solar, biomass, and geothermal energies is particularly high. In recent years, intensive efforts have been made to determine the potential of these energy sources and to increase production values. As in the rest of the world, renewable energies are gaining more importance in our country’s energy policy every day. The tables below show Türkiye’s renewable energy activities and its targets up to 2019.

As seen in the tables above, solar energy has taken a significant position among renewable energy sources with its rising trend in recent years.

4. What Cables Are There in a Solar Energy Systems?

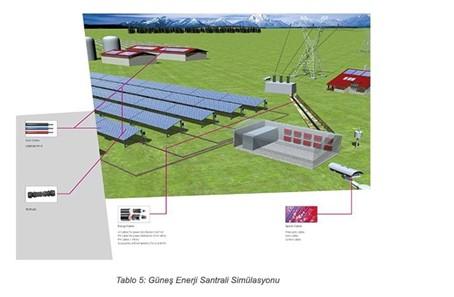

As seen above, there are three types of cables in a solar power plant.

These are:

- DC Cables

- AC Cables

- Control and communication cables

In a solar power plant, the cables most exposed to external influences are the solar (PV – Photovoltaic) cables on the DC side. So, what conditions are expected for a solar (PV) cable?

- 25-year lifespan

- AC: 1kV, DC: 1.5kV

- Fire resistance • According to EN 50618, Table-2

- Single Cable Flame Test according to EN 60332-1-2 standard

- Low Smoke Density according to EN 61034-2 standard (Light transmittance >70%)

- Halogen-free according to EN 50525-1, Annex-B standard • Operating temperature (90ºC)

- Cold resistance -40ºC

- UV and ozone resistance

- Resistance to nature

- Pressure resistance

- Acid resistance

- Flexibility

- Easy identification and color fastness

- Environmentally friendly

5. Current Status of Solar Cable Standarts

When we examine the standards defined for the cables used in the system, an interesting situation emerges. Since AC, control, and communication cables are used in other systems as well, standards for these cables have largely been established worldwide. However, international standards for solar (PV) cables, which are exposed to the most challenging conditions of the system, have only recently begun to emerge due to the relatively young age of solar energy systems compared to other energy systems globally.

Germany has been leading this effort, with technical documents created by the “DKE AK” and TÜV working groups, which form the basis of international standards, first being used in Germany and later forming the foundation of the newly established EN norms.

The development of this issue in Germany and Europe can be briefly summarized as follows:

In Europe, until August 2007, there was no cable test document or standard for solar (PV) cables used in solar energy systems, so 450/750 V PVC cables listed in harmonized standards were used.

Due to the lack of high resistance to conditions such as ozone, UV, and high temperatures (Max. 120°C) in these types of cables, a standard working group named AK 411.2.3 was formed for photovoltaic cables within the DKE-Deutsche Kommission Elektrotechnik (German Electrical Commission) standard working groups. The technical document created by the AK 411.2.3 working group, which defines solar (PV) cables, later formed the basis of the 2PfG 1169 document created by TÜV. After the publication of TÜV’s 2PfG 1169 document, solar (PV) cables began to be requested in accordance with this document in both Germany and our country. Additionally, compliance with the tests defined in the TÜV 2PfG 1169/2007.08 document has emerged as another criterion for solar (PV) cables.

However, since the TÜV 2PfG 1169/2007.08 document does not have the status of a standard, the VDE-AR-E 2283-4 document was put into effect on 01.10.2011 for solar cables by VDE, with the approval of the AK 411.2.3 working group and, in the final stage, the UK 411.2 national working group. The VDE-AR-E 2283-4 document was also submitted to the CENELEC TC20 international working group to initiate an EN standard study.

As a result of a four-year standard study across Europe, the EN 50618 Standard will come into effect on 27.10.2015.

Germany will repeal the VDE-AR-E 2283-4 and TÜV 2PfG 116/07.2008 documents, which were in effect before the EN 50618 standard, as of 27.10.2015. Additionally, a transition period has been set until 27.10.2017 across Europe. By this date, all “country-specific standards” within Europe will be repealed.

The EN 50618 standard was published and came into effect in the UK in January 2015, in France in March 2015, in Spain in March 2015, and in Turkey in February 2015.

6. Importance of Selecting Materials

In Europe, photovoltaic plants reaching MW capacities were first established in Spain in 2006, followed by plants in Italy, Germany, and other European countries. The experiences during the operation of these plants have shown that the materials chosen for the system have a significant impact on the gains obtained from the system. In facilities where quality materials are used, the return on investment (ROI) time is very short, and the return and efficiency obtained from the system are very high. Conversely, in facilities where poor-quality materials are used, the ROI time is extended, the costs of poor quality are very high, and this situation causes serious financial losses. However, the poor-quality materials used in these systems start to cause problems from the 3rd or 4th year, although the exact time is not certain, and when the system is supposed to start making money, it reduces the efficiency of the system, preventing the gains and additionally causing extra costs (replacement, time losses, labor, etc.).

For an investor investing in a solar energy system, the amortization period is approximately 6-7 years according to today’s costs; that is, an investor investing approximately 1M€ for a 1 MW system starts to receive all the income from the system after 6-7 years. Therefore, it is expected that the system will work without any problems for at least 6-7 years and then have a maximum lifespan to maximize the investor’s income; this is the main expectation of every investor who invests in the system. TÜV and EN test documents and standards require a 25-year lifespan for cables; however, it is important to note that this lifespan should not be confused with a guarantee. Therefore, the quality of the selected products becomes even more important, and additionally, it is crucial that the manufacturer of the product is experienced in this field, stands behind their product, and has a reliable technical and financial infrastructure to provide long-term support.

Within a solar energy system, the proportion of the cable in the total system cost is less than 2%. Despite being a very small part of the total cost of the system, the necessary care is unfortunately not taken in the selection of the cable, which plays a key role in system performance. As a result of choosing poor-quality cables, there can be significant losses in system efficiency; the produced energy cannot be transmitted to the system at full capacity; cables affected by external environments need to be replaced from time to time, and all these factors hinder the potential gains. Additionally, unforeseen labor and extra material costs also arise. People dealing with solar energy systems will, after a while, better understand the cost and difficulty of replacing cables behind panels due to a problem caused by the cable.

7. Conclusion

Looking at the history of solar systems, we can say that these systems are actually very young. Considering that the test documents for these systems have been in effect since 2008 and that a 25-year lifespan is expected from a solar system, it is very clear that there is currently no system that has completed its lifespan. Therefore, it is very important that the suppliers producing the products to be used in these systems have long-term experience in the field and that their products have been tested not only in laboratories but also in real use. Although good results are obtained in material laboratory tests, we have seen in Europe over the past three years that products perform completely differently in the field due to very different environmental conditions. Ultimately, some companies producing cables for this sector have completely left the sector in many countries, including Germany, due to negative experiences, and it has been observed that investors using these products in their systems could not find a counterpart after a while. In fact, another reason for the bankruptcy of companies using the cheapest cables and other materials from inexperienced manufacturers in Europe is this.